£45.56 – £144.32 (Ex VAT)

Maintenance Spill Kit / Refill 60L Blue Barrel

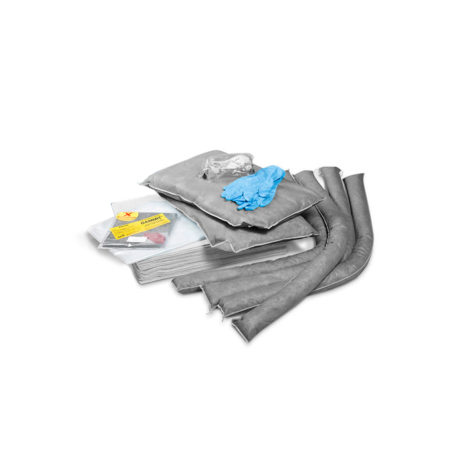

This small sized maintenance spill kit, also known as a general purpose spill kit, contains a range of general purpose absorbents that are suitable for use inside and out. It is ideal for spills, leaks, drips of non-corrosive liquids, hydrocarbons, solvents, other aqueous, and organic liquids.

The blue barrel is made from polyethylene and has an open top with a snap ring lid. There are handles either side for easy positioning. The barrels are suitable for outdoor and indoor use where there is risk of liquid spills.

Maximum absorbency capacity 60 Litres

Description

Maintenance Spill Kit / Refill 60L Blue Barrel

This small sized maintenance spill kit, also known as a general purpose spill kit, contains a range of general purpose absorbents that are suitable for use inside and out. It is ideal for spills, leaks, drips of non-corrosive liquids, hydrocarbons, solvents, other aqueous, and organic liquids.

The blue barrel is made from polyethylene and has an open top with a snap ring lid. There are handles either side for easy positioning. The barrels are suitable for outdoor and indoor use where there is risk of liquid spills.

May be safely used with all aqueous solutions and liquids immiscible with water, such as hydrocarbons, solvents, mineral oils, with the exception of strong oxidising agents. Before any use in a spill situation a proper risk assessment should be carried out and all hazardous properties of the liquid or dangerous reactions taken into account.

Maximum absorbency capacity 68 Litres

Maintenance Spill Kit Contents:

|

TrainingIf you are unsure of how to use absorbents, we have high quality 17 minute Spill Response and Pollution Prevention Training Video. It is available from Spills Kits Direct SKU: 504/04001

|

||||||||||||||||||

Features and benefits

Fire resistance

Disposal

|

Recommended usage

Classification of waste

Tested in accordance with:-

|

Question: What is the ISO 10319:2024 standard?

Answer: In brief it is a tensile test. The standard specifies a tensile test method that covers the measurement of tensile force, elongation characteristics and includes procedures for the calculation of secant stiffness, maximum load per unit width and strain at maximum force. Singular points on the tensile force-extension curve are also indicated. Procedures for measuring the tensile properties of both conditioned and wet specimens are included in this document.

Question: What is the BS 7959-1:2004 standard?

Answer: In brief it is used to assess sorbency. The standard looks at the sorbent materials. These are generally available in two basic types. There are hydrophobic grades (so-called oil sorbents) that pick up oils and other organic liquids but repel water and most aqueous solutions. Hydrophilic grades, on the other hand, pick up both oils and organic liquid and most aqueous solutions of chemicals. The absorbency (litres of liquid absorbed per kg) is greatly influenced by the liquid viscosity and drainage time. We quote minimum absorbencies based on laboratory tests carried out using SAE10W40 motor oil in line with the British Standard Test Method BS7959-1:2004 (30 second drainage time, at 20C) and maximum absorbencies with no drainage.

Answer: In brief it is used to assess sorbency. The standard looks at the sorbent materials. These are generally available in two basic types. There are hydrophobic grades (so-called oil sorbents) that pick up oils and other organic liquids but repel water and most aqueous solutions. Hydrophilic grades, on the other hand, pick up both oils and organic liquid and most aqueous solutions of chemicals. The absorbency (litres of liquid absorbed per kg) is greatly influenced by the liquid viscosity and drainage time. We quote minimum absorbencies based on laboratory tests carried out using SAE10W40 motor oil in line with the British Standard Test Method BS7959-1:2004 (30 second drainage time, at 20C) and maximum absorbencies with no drainage.

Additional information

| Weight | N/A |

|---|---|

| Absorbency capacity | Up to 60 L |

| Container | Drum |

| Spill kits | Maintenance Spill Kits |

| Product type | Maintenance |

| Container capacity | 60 litres |

| Kit Type | Complete kit in a container, Complete kit in a container and a refill kit, Refill kit only (no container) |

| Type | Maintenance | Oil | Chemical |

|---|---|---|---|

| Acetic acid (100%) | Excellent | Not recommended | Excellent |

| Acetone | Excellent | Excellent | Excellent |

| Acrylonitrile | Excellent | Excellent | Excellent |

| Ammonia | Moderate | Not recommended | Good |

| Aniline | Moderate | Good | Excellent |

| Beer/wine | Excellent | Not recommended | Excellent |

| Blood | Excellent | Not recommended | Excellent |

| Bottled water | Excellent | Not recommended | Excellent |

| Brake fluid | Excellent | Excellent | Excellent |

| Carbon tetrachloride | Excellent | Excellent | Excellent |

| Carbonated soft drinks | Excellent | Not recommended | Excellent |

| Carbonic acid | Excellent | Not recommended | Excellent |

| Chloroform | Excellent | Excellent | Excellent |

| Crude oil | Excellent | Excellent | Excellent |

| Cyclohexanone | Excellent | Excellent | Excellent |

| Diesel oil | Excellent | Excellent | Excellent |

| Diethylamine | Excellent | Excellent | Excellent |

| Dilute acids & alkalis | Excellent | Not recommended | Excellent |

| Dilute bleach | Excellent | Not recommended | Excellent |

| Electrical transformer oil | Excellent | Excellent | Excellent |

| Ethanol 100% | Excellent | Excellent | Excellent |

| Ether | Excellent | Excellent | Excellent |

| Ethylene glycol | Excellent | Excellent | Excellent |

| Formaldehyde | Excellent | Excellent | Excellent |

| Formic acid | Not recommended | Not recommended | Excellent |

| Fuel oil | Excellent | Excellent | Excellent |

| Fuming nitric acid | Strongly not recommended | Strongly not recommended | Strongly not recommended |

| Fuming sulphuric acid | Strongly not recommended | Strongly not recommended | Strongly not recommended |

| Gastric stomach acid | Excellent | Not recommended | Excellent |

| Heating oil | Excellent | Excellent | Excellent |

| Hexane | Excellent | Excellent | Excellent |

| Hydraulic oil | Excellent | Excellent | Excellent |

| Hydrochloric acid (35%) | Not recommended | Not recommended | Excellent |

| Hydrofluoric acid | Not recommended | Not recommended | Excellent |

| Hydrogen peroxide (10%) | Moderate | Not recommended | Excellent |

| Industrial waste water | Excellent | Not recommended | Excellent |

| Jet Fuel | Excellent | Excellent | Excellent |

| Kerosene | Excellent | Excellent | Excellent |

| Liquid animal fat | Excellent | Excellent | Excellent |

| Liquid chlorine | Strongly not recommended | Strongly not recommended | Strongly not recommended |

| Liquid manure | Excellent | Not recommended | Excellent |

| Methanol | Excellent | Excellent | Excellent |

| Methylene chloride | Excellent | Excellent | Excellent |

| Milk | Excellent | Not recommended | Excellent |

| Mineral oil | Excellent | Excellent | Excellent |

| Motor oil | Excellent | Excellent | Excellent |

| Nitric acid (71%) | Not recommended | Not recommended | Excellent |

| Oil on water | Not recommended | Excellent | Not recommended |

| Peracetic acid | Not recommended | Not recommended | Not recommended |

| Perchloric acid | Strongly not recommended | Strongly not recommended | Strongly not recommended |

| Petrol | Excellent | Excellent | Excellent |

| Phenol | Excellent | Excellent | Excellent |

| Potassium hydroxide | Not recommended | Not recommended | Good |

| Salt water | Excellent | Not recommended | Excellent |

| Soapy water | Excellent | Moderate | Excellent |

| Sodium carbonate | Moderate | Not recommended | Good |

| Sodium hydroxide | Not recommended | Not recommended | Good |

| Sodium hypochlorite | Moderate | Not recommended | Excellent |

| Sulphuric acid (98%) | Not recommended | Not recommended | Excellent |

| Surgical spirit | Excellent | Excellent | Excellent |

| Tap water | Excellent | Not recommended | Excellent |

| Toluene | Excellent | Excellent | Excellent |

| Trichloroethylene | Excellent | Excellent | Excellent |

| Trifluoroacetic acid | Not recommended | Not recommended | Excellent |

| Trisodium phosphate | Not recommended | Not recommended | Good |

| Vegetable oil | Excellent | Excellent | Excellent |

| Vinegar | Excellent | Not recommended | Excellent |

| White spirit | Excellent | Excellent | Excellent |

Delivery lead-times

We do try, where possible, to deliver on a next day basis. This is always subject to stock, forward orders and courier availability. We recommend that you allow for our estimated delivery timescales of:-

- 1-2 days Absorbents & Kits

- 3-7 days Containment & Mats

- 10 days+ Flood products

Please contact us for a guaranteed next day service, we will do our best to arrange this for you.

Standard Delivery Charge

- Our standard delivery charge is £18.00 + VAT for orders up to 25 kgs.

- Orders over 25 kgs are charged for by weight and vary depending upon postcode.

Large and Heavy Items

- Products that are large, bulky and heavy will normally incur additional charges as these ship on pallets.

- Any additional charges will be displayed in the shopping basket once the delivery address has been entered.

- Where items include “FREE to England and Wales” surcharges will be applied for postcodes not deemed to be within these areas and may include some islands.

Postcode restrictions

- Certain areas within the UK attract additional surcharges, these include Scotland, Highlands & Islands, Northern Ireland and the Channel Islands.

Delivery times

- We aim to delivery during normal business hours (8:00am – 6:00pm) Monday to Friday.

- Standard delivery times are 2 – 3 days however this is always subject to stock availability and forward orders.

- For order received before 12:30hrs, we aim to process these same day. Orders placed after 12:30hrs will be processed the following working day.

- If you need to let us know of any special delivery instructions please provide these at checkout.

- It is really important to provide as much information as possible.

- If we are unable to deliver as arranged, then we reserve the right to levy an additional charge for the second attempted delivery.

- Please note that we will not attempt a third delivery, your order will be returned to us.

EU and international shipping

- We ship to European and international destinations through our network of trusted and approved logistic / freight forwarders.

- If you would like a quotation please get in touch.